Ground improvement techniques are geotechnical construction methodologies that modify and enhance the engineering properties of the soil mass by improving one or more of the following parameters: Increase in the soil density and shear strength, decrease of the compressibility, reduction of settlement (total and differential), increase in the soil bearing capacity, acceleration of the consolidation process, increasing the factor of safety against liquefaction in case of an earthquake and generally, restrengthening of the soils. There are a number of Ground Improvement Techniques available for different types of soils, different purposes and project requirements.

Vibro Compaction is a densification ground improvement technique that rearranges the soil particles into a denser state. Vibro Replacement is a reinforcement ground improvement technique that strengthens the soil by means of the construction of a stone column.

Dynamic Compaction is a densification ground improvement technique that uses a heavy weight “tamper” suspended from a crawler crane boom that is dropped a repeated number of times into the ground to densify the soil.

RIC is a ground improvement technique consisting of an excavator-mounted, hydraulic pile-driving hammer of 9-16 ton hydraulically raised and then allowed to free-fall, thus delivering energy to arrange soil particles into a denser state.

HIRC is also a “dynamic” compaction technique consisting of a triangular, rectangular or hexagonal ”wheel” mounted on a trailer that is pulled by a tractor with a constant speed, making several passes compacting the soil.

Vibro Compaction is a technique that enables the rearrangement of soil particles into a denser configuration with vibration by the use of powerful downhole deep vibrating probes.

Vibro Replacement (Stone Columns) uses the same principle as the Vibro Compaction (powerful vibroflots that generate vibration to rearrange soil particles), but in soils where VC is not possible due to higher fines content (higher than 10% and typically less than 40%). Hence, the densification is achieved by displacement of the soils radially by the vibrator, refilling the resulting space with granular material which results in the construction of stone columns at the treatment locations.

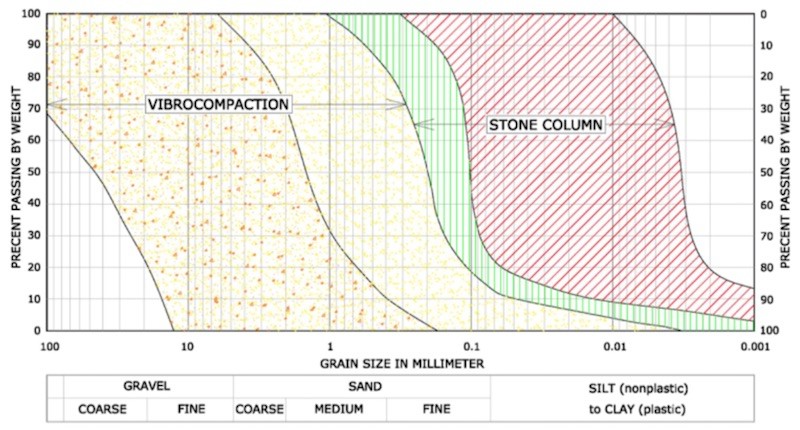

The Vibro Compaction technique is best suited for loose sand to coarse-grained soil with a silt/clay content of less than 10% (less efficient with a fines content between 10% and 15%). The technique applies to depths up to 45m (or more, depending on the crane capacity). The Vibro-Replacement (stone columns) is most suitable for sand with a fines content of more than 10% and usually less than 40% or for clays that require a certain degree of bearing or lateral reinforcement. The technique applies to depths up to 45m (or more, depending on the crane capacity).

Dynamic Compaction (DC) involves the repeated dropping of a 10 to 30-Ton tamper multiple times from heights of 15m to 30m, transforming potential energy into a densification effect to the soil particles.

The DC technique is most suitable for loose medium to coarse-grained sands with silt / clay content less than 15% (somehow efficient with fines content between 15% and 20%). It can be applicable for depths up to 12m, but the typical ideal effective depth is down to 10m.

DDC is effective both above and below the ground water table although vertical drain elements (such as wick drains) are typically used to assist with pore water dissipation when the water table is relatively shallow.

RIC is a ground improvement technique consisting of an excavator-mounted, hydraulic pile-driving hammer of 9-16 ton hydraulically raised and then allowed to free-fall, thus delivering energy to arrange soil particles into a denser state. RIC is both a densification and a reinforcement technique. It uses the same principle as the Dynamic Compaction (weight dropped into the ground to densify the soil), but in a more controlled manner (less height, less weight, but faster). On the one hand, it is a densification technique because it rearranges the soil particles into a denser state. On the other hand, it can also be a reinforcement technique. When combined with soil replacement or stone backfill at the point of impact, it develops reinforced columns that are built and compacted with this method, thus increasing the bearing capacity, limiting the settlement (total and differential) and increasing the shear strength.

The RIC technique is most suitable for loose medium to coarse-grained sands with silt / clay content less than 20% (less efficient with fines content between 20% and 25%). It can be applicable for depths up to 5-6m with 9 ton hammers and up to 8-9m with 16 ton hammers. The depth of improvement highly depends on the soil conditions.

HIRC is a “dynamic” compaction technique consisting of a triangular, rectangular or hexagonal ”wheel” (typically between 8 and12 Tons) mounted on a trailer that is pulled by a tractor with a constant speed, making several passes over the soil. The effect of the speed combined with the “tampering” of the irregular “wheel” creates a waving effect that densifies the soil particles.

Unlike the principle of the weight dropped from a height (i.e. Dynamic Compaction and High Impact Compaction) the “weight” of the HIRC is “pulled” from a tractor, making each turn of the odd shape “wheel” an energy impact wave delivered into the ground, hence densifying the soil. The depth of densification is less than the Dynamic Compaction or Rapid Impact Compaction. Therefore, HIRC is considered a superficial compaction method.

The High Impact Rolling Compaction technique is applicable for sands with fines content not in excess of 10%, but can also be used (with less effectiveness) with slightly greater fines content. HIRC has a limited depth of improvement to the top 1.5m to 2.0m. It is ideally implemented as complementary to other deep compaction methods like VC or DC, which are poor in compacting superficial soils.