Vacuum Consolidation is a soft soil ground improvement method that is typically combined with Prefabricated Vertical Drains and Horizontal Drains (PVD+VCM) and basically is a solution to replace the use of a surcharge. Further to the installation of the PVD, it consists of the application of a suction force with vacuum to an isolated mass of soil in order to reduce the atmospheric pressure and excess water pore pressure present in the soil, resulting in a consolidation of the soil, an increase in the effective stresses without modifying the total state stresses.

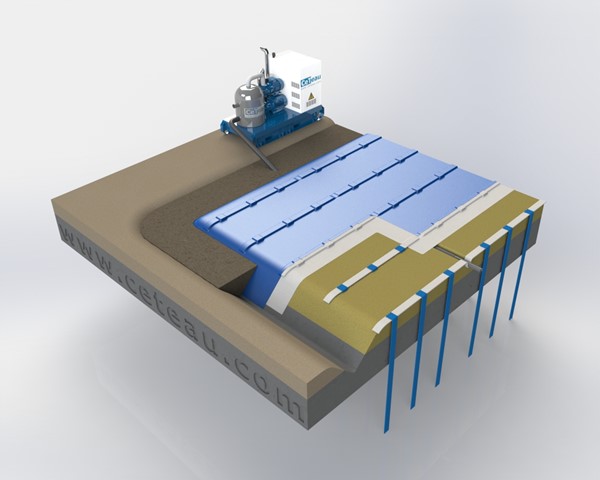

The vacuum consolidation system consists of the installation of a drainage system (PVD) and Horizontal Drains, an isolation system and vacuum pumps. Once initialized, the vacuum is quickly distributed in the soil through the drainage system, reducing atmospheric pressure and excess pore pressure, creating a pressure differential between the prefabricated vertical drains (PVD) and the pore pressure present in the soils. This difference in pressures causes the water to flow vertically through the drain, causing a consolidation effect.

Because the force used is a result from the vacuum effect of the atmospheric pressure, VCM eliminates the need of the surcharge after installation of the PVD´s and thus, it eliminates the associated costs of the surcharging process.

The Vacuum Consolidation Method (VCM) is applicable for very soft to soft clays or silty clays with water and plasticity content. These types of soils are typically deemed unsuitable for any engineering use and on many occasions are recommended to be removed from site and to be replaced with expensive granular soils. With VCM, the “bad soil” becomes treatable and consequently useful for engineering purposes. The depth is limited by the thickness of the soft deposit and the capacity of the PVD installing machine. VCM projects can have depths of treatment in the range of 10, 15, 20, or 35m and even up to 45m.